LS screw conveyor is a mechanism that uses a rotating helical screw blade, usually within a trough to move granular and powdery materials. It is used in many bulk handling industries, installed horizontally or at a slight incline as an efficient way to move the materials.

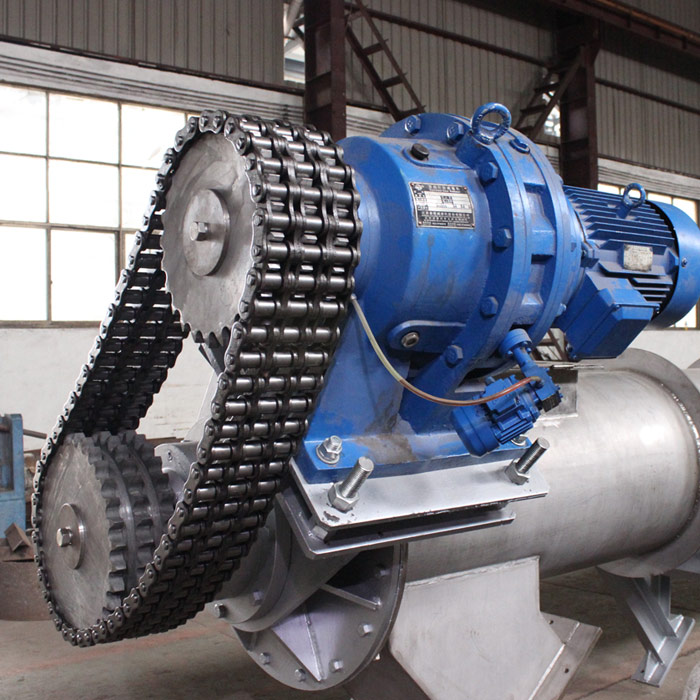

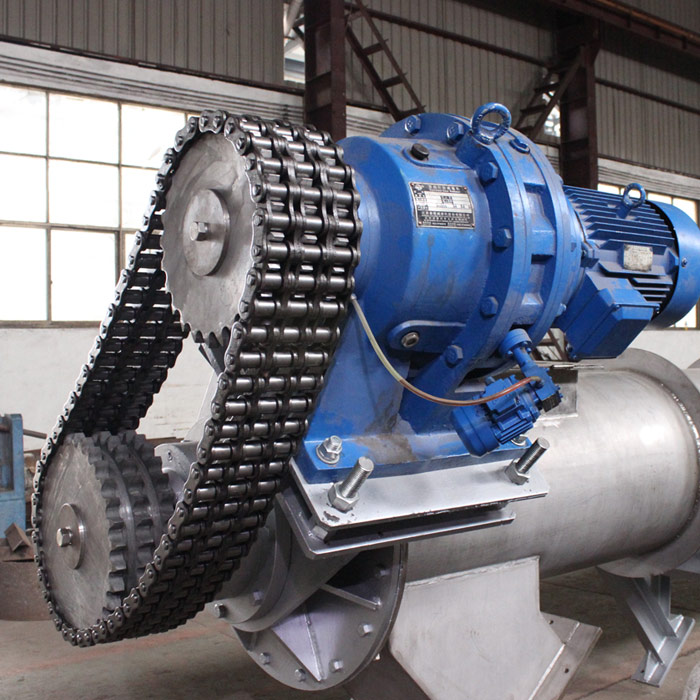

LS screw conveyor usually consists of a trough containing either a spiral blade coiled around a shaft, driven at one end and held at the other. The main parts include trough, shaft with spiral blades, inlet and outlet chutes, as well as the driving device. The rotating part of the conveyor is sometimes called simply an auger.

The conveying capacity is proportional to the rotation rate of the shaft. It can be operated with the flow of material inclined upward. When space allows, this is a very economical method of elevating and conveying. As the angle of inclination increases, the capacity of a given unit rapidly decreases.

Simple structure, good sealing, large capacity, long service life.

Convenient installation and maintenance, as well as easy operation.

Working temperature is -20~50°C, with material temperature below 200°C.

The conveying length is up to 70m.

Suitable for horizontal and slightly inclined transport of powdery, granular material.

| Model | Screw

Diameter |

Screw

Pitch |

n-Rotation Speed (r/min), Allowable Deviation < 10%

Q-Capacity (m3/h), Filling Factor = 0.33 |

|||||||

| (mm) | (mm) | n | Q | n | Q | n | Q | n | Q | |

| LS 160 | 160 | 160 | 112 | 8 | 90 | 7 | 71 | 6 | 50 | 4 |

| LS 200 | 200 | 200 | 100 | 14 | 80 | 12 | 63 | 10 | 50 | 7 |

| LS 250 | 250 | 250 | 90 | 24 | 71 | 20 | 56 | 16 | 45 | 13 |

| LS 315 | 315 | 315 | 80 | 34 | 63 | 26 | 50 | 21 | 40 | 16 |

| LS 400 | 400 | 355 | 71 | 64 | 56 | 52 | 45 | 41 | 36 | 34 |

| LS 500 | 500 | 400 | 63 | 100 | 50 | 80 | 40 | 64 | 32 | 52 |

| LS 630 | 630 | 450 | 50 | 145 | 40 | 116 | 32 | 94 | 25 | 80 |

| LS 800 | 800 | 500 | 40 | 208 | 32 | 165 | 25 | 130 | 20 | 110 |

| LS 1000 | 1000 | 560 | 32 | 300 | 25 | 230 | 20 | 180 | 16 | 150 |

| LS 1250 | 1250 | 630 | 25 | 388 | 20 | 320 | 16 | 260 | 13 | 200 |

Note: The data in this table is for reference only, and the actual parameters are determined according to user needs.